Enter The TAOCASTER

3D Printed Design Aid shaped like a Guitar

Table Full of Content

2+ Years in the making and never finished

For my Spring 2025 Senior Project, I wanted to do something technical, challenging, and fun. I adapted an electric guitar, an Industrial Design Classic using additive best practices and core ID principles.

Despite never touching an instrument in my life prior, how hard could it be…

Fall 2023/ Project Start: What is a relatable Product that incorporates traditional Industrial Design Principles, which is ideal to 3D-Printify and elevate the medium?

Electric Guitar Chosen for:

+ Multi-Material Construction

+ Modern Manufacturing

+ Historical Design Legacy

+ Functional & Aesthetic object

+ It’s Cool

Spring 2024/ Final Commitment: Spend the next year+ learning to play guitar as research with no musical background.

While also defining guitar quality and what parts can/should be 3D printed, etc...

October 2024/ Halftime Show: Quick 40hr side project Halloween Weekend mostly as a preamble to learn the mechanics of how a guitar works.

Resulting in THE SPELLBOUND: 3-String Necronomicon Guitar

December 2024/ Concept Refinement: Most of this period was really defining what this product wanted to be beyond just “3D printed Guitar”. Having an emphasis on marketing and manufacturability as part of pre-production.

Spring 2025/ Prototyping + Final Showcase: Everything before this was pretty much all theory and I had no idea how the real was going to come out. It was a pretty nerve-racking couple of months.

Phase I: String Tension Testing

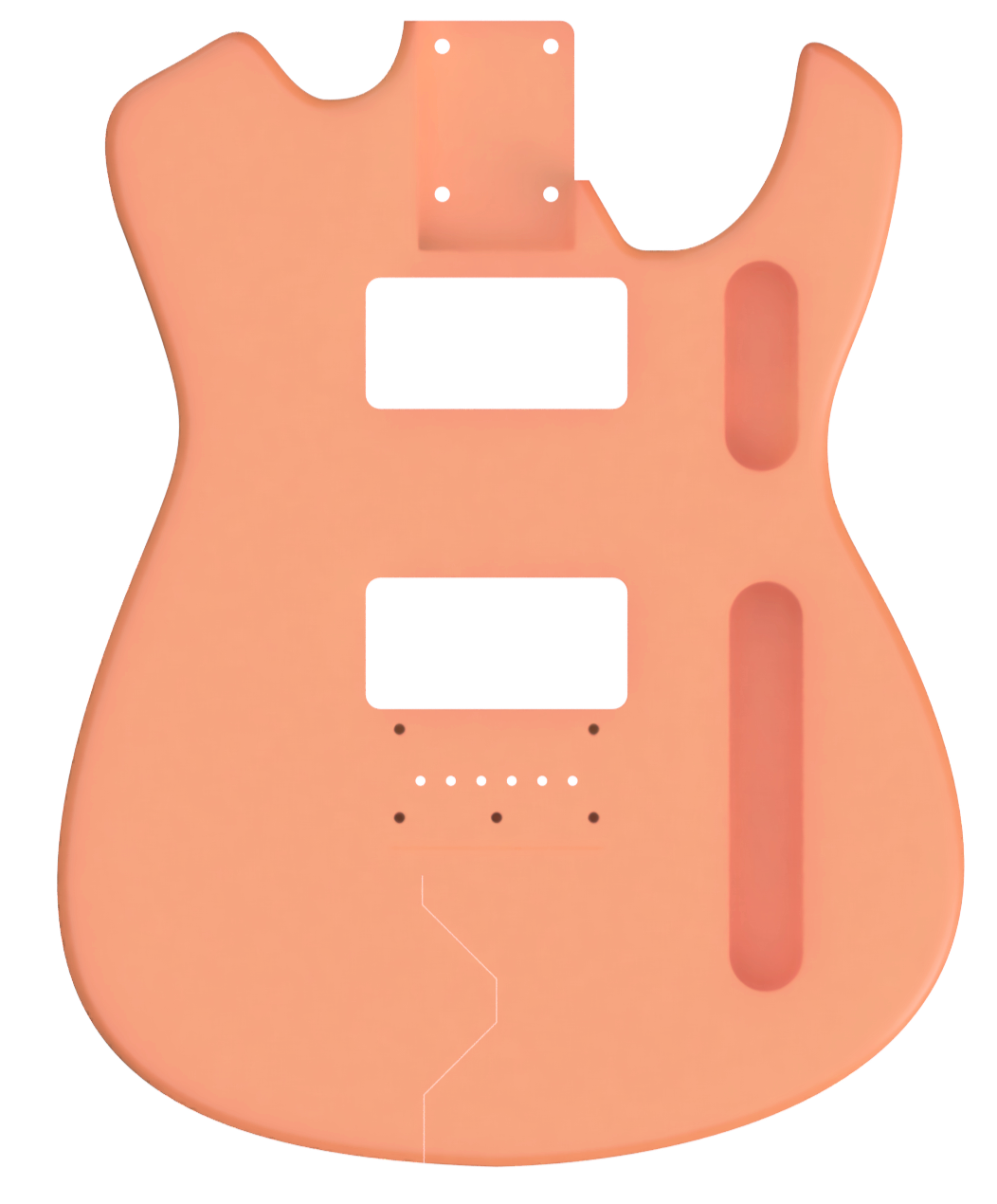

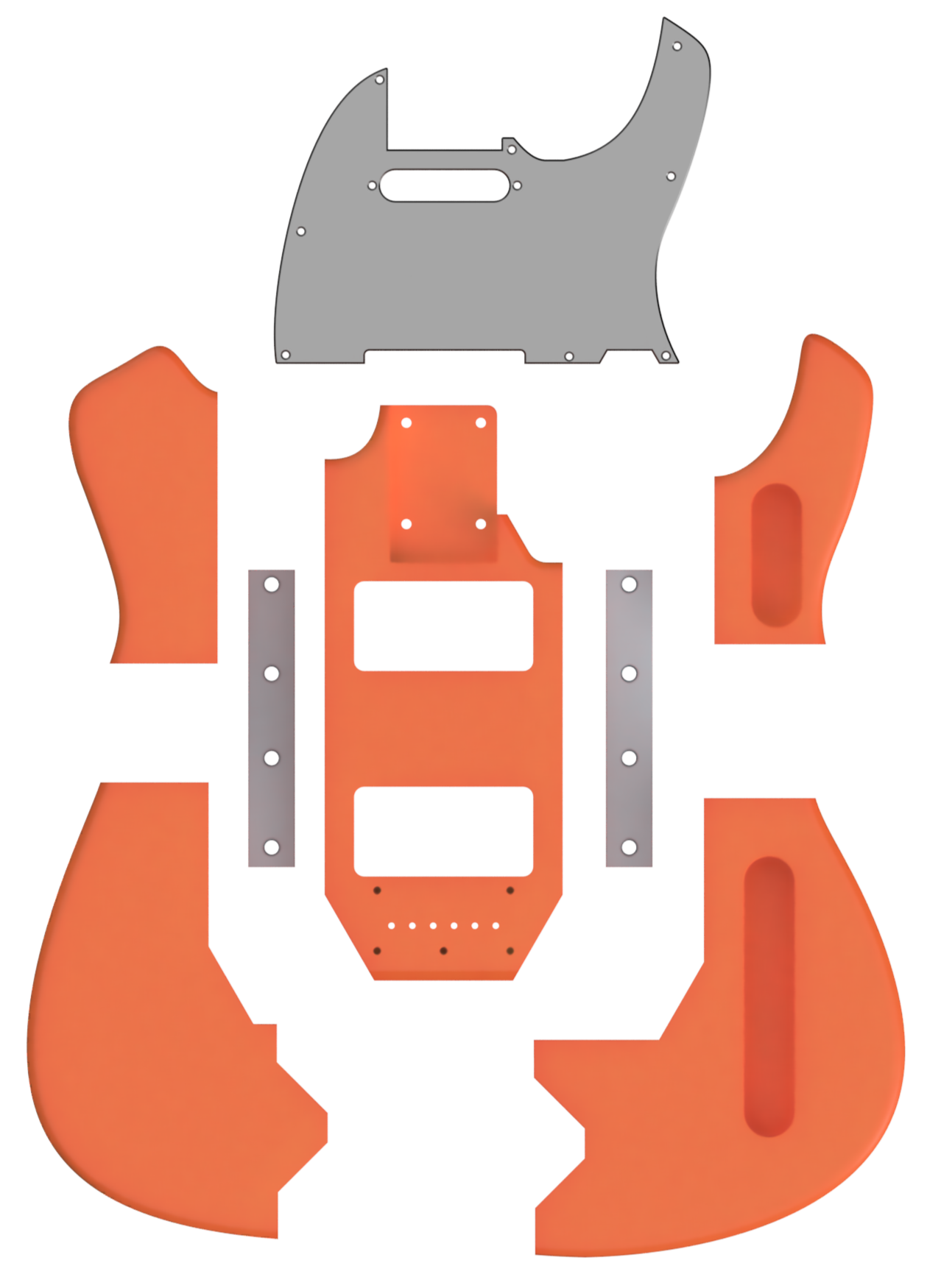

Phase II: Body/ Assembly Fitting

Phase III: Production

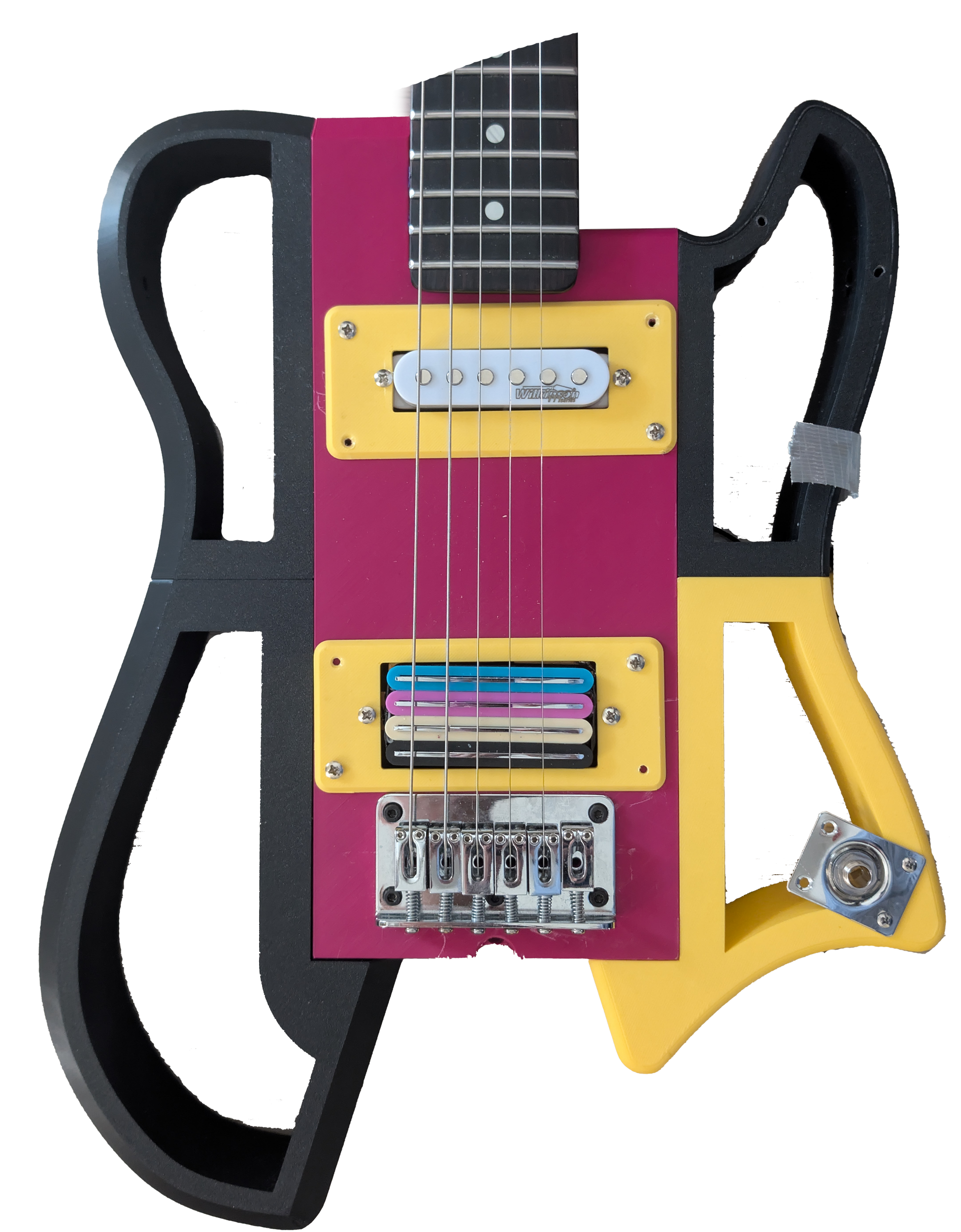

TELEMARKETER

TAOCASTER

The TAOCASTER: Direct Digital Manufacturing Personified

Unparalleled Design flexibility provides adaptable shapes with ergonomics not seen in most guitars. Providing preference, without compromising utility

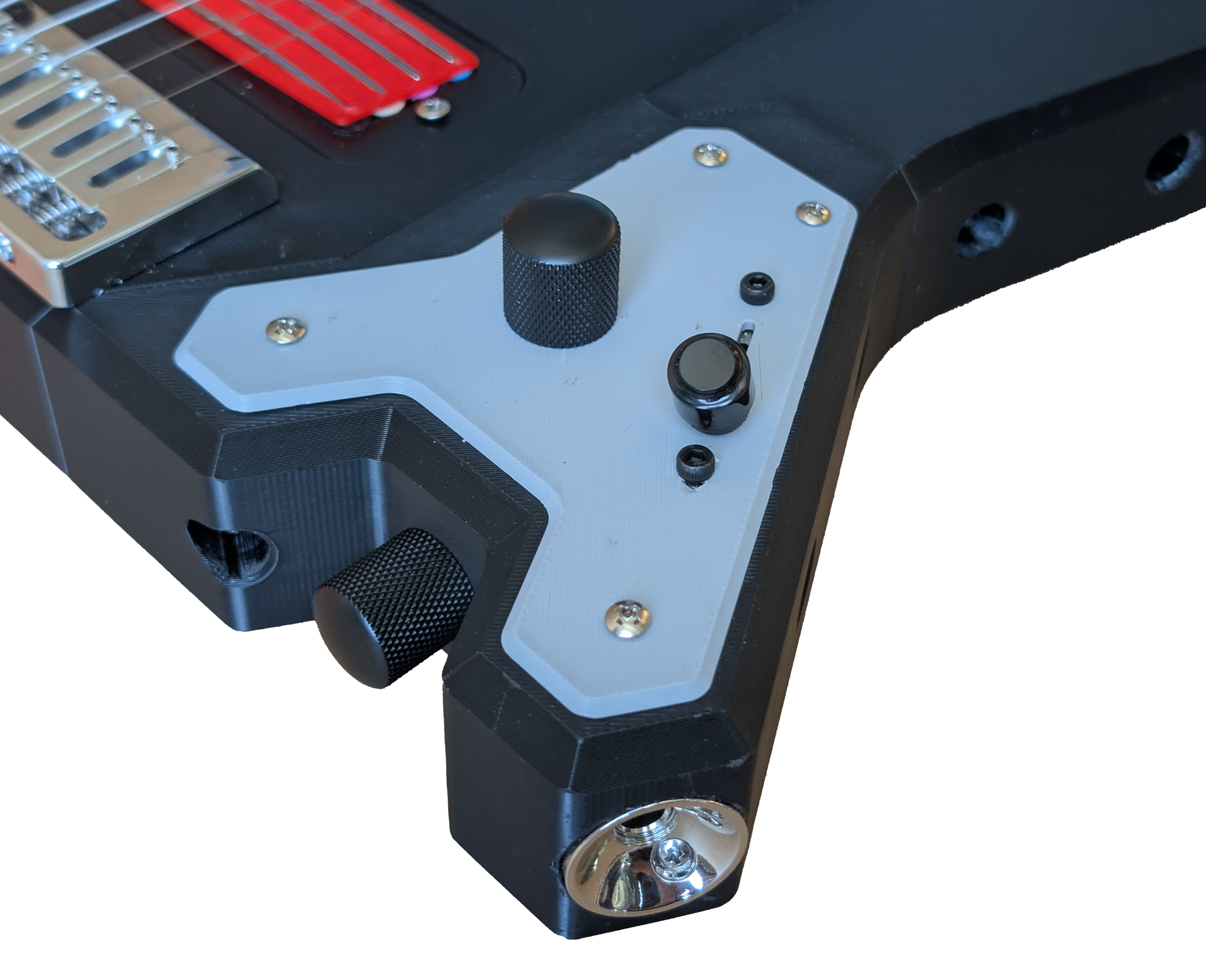

The TELEMARKETER: Modern Manufacturing in a classic style

Given the robustness of 3D printing, the Telemarketer is meant to be a more familiar take in contrast to the less conventional stylings of the Taocaster Flagship design.

It’s Real! Right here. Right now.

For me, the final deliverable couldn’t be an early prototype, a hypothetical concept, or just a bunch of sketches and renders. It had to be a real working instrument that people could see, touch, and hear.

Because sometimes the best way to show someone your idea is to just get it in their hands.

Alex Komodore, Classical Guitarist/ MSU Denver Music Professor

Famous Artist or whatever (@jessica.j.mccormick) + Willow the Possum

Next Up

I have a lot of fun ideas and future improvements for the next-generation TAOCASTER II whatever form that takes. This is a passion project first, so I don’t have any immediate plans to bring this to market.

Though if I did, that business model would take full advantage of Direct Digital Manufacturing and probably look something like this:

Just the digital files: $

Printed Body only: $$

Full Build Kit: $$$

Complete Guitar: $$$$